Rubber today looks different than the rubber of yesteryear. For better, worse, and plenty of in-betweens, rubber specialists have experimented with, expanded upon, and advanced processes to improve the material that’s literally everywhere today.

Here we take a closer look at the milestones that revolutionized rubber in our series “How It Changed Rubber Forever,” and one of the most impactful events that changed rubber indefinitely was World War II (WWII).

Rubber and World War II in a Nutshell

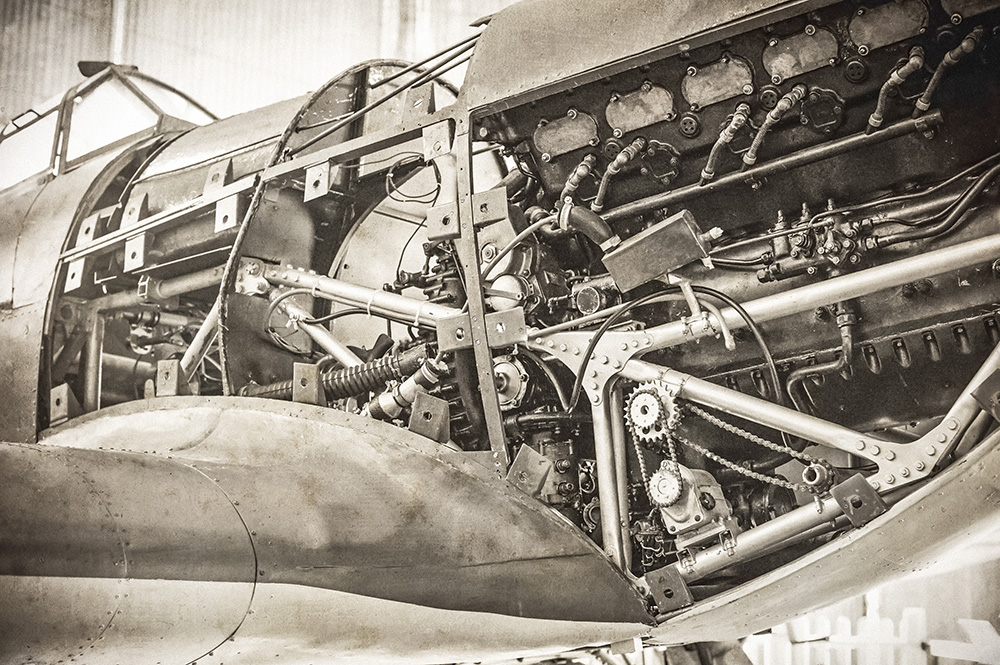

Rubber was a vital commodity during the war. It was used to create parts, components, and compounds in vehicles, hospitals, uniforms, and more.

World War II influenced changes in the means of production, impacted the creation of new materials, and resulted in technologies, products, and so much more that the details could fill volumes.

Here, we boil down the big moments to give you a compact look at how rubber changed during WWII.

Rubber Before World War II

Natural latex rubber was still the rubber of choice until the mid-1800s because nothing else existed. That’s not to say natural rubber and its properties weren’t advanced during this time. Qualities like waterproofing, enhanced durability, various resistances, and more were used in things like bicycle tires, raincoats, and rubber bands and belts.

Material scientists around the world enhanced the natural properties of rubber through milestone discoveries before WWII, and this resulted in some of the most well-known processes and compounds still in use today.

Early rubber advancements before World War II include:

- 1830 – 1850s – Thomas Hancock and Charles Goodyear developed the vulcanization process and fought over its patent

- 1909 – Isoprene was developed at a Bayer laboratory

- 1930 – Neoprene was developed by the Dupont company

- 1930s – Oil-resistant Buna rubber was developed in Germany

- 1935 – Additional co-polymer synthetic rubbers were created in Germany, Russia, and North America

- 1937 – Standard Oil adapted Buna rubber to create butyl rubber

Germany invaded Poland on September 1, 1939, which officially started WWII and forever altered rubber, manufacturing, and the lives of countless people around the world.

Rubber During World War II

Natural rubber sourcing and synthetic rubber production were essential during the early years of the war for all countries involved. Rubber in its many forms was used in countless products across innumerable applications and was in high demand.

The day after the bombing of Pearl Harbor on December 7, 1941, Japan captured Singapore—the center of the world’s natural rubber production for the Axis powers. Essentially 90% of Allied access to natural rubber was cut off.

The amount of rubber used for war in the 1940s included:

- 32 pounds of rubber per soldier for footwear, clothing, and equipment

- 1,000 pounds of rubber for one military airplane

- Approximately 2,000 pounds of rubber for one tank

- 75+ tons of rubber for one battleship

The United States alone used half of the world’s natural rubber supply by the late 1930s, most of which came from Southeast Asia. With this supply gone, synthetic rubber development and salvage efforts ramped up exponentially, and rubber innovation and mass production became vital to success.

In January 1942, the Salvage for Victory campaign was launched in the United States, which urged businesses and individuals to pledge to save scrap metal, rags, rubber, and other materials to help the war effort. And more than 50 factories in the United States manufactured what was called Government Rubber Styrene by 1944 to make up for the loss of natural rubber.

Conversely, synthetic rubber plants were both erected and targeted for bombing runs throughout Europe between 1941 and 1945 in an effort to maintain and suppress the supply of rubber to Ally and Axis countries.

World War II and the economies of war that supported it all relied on rubber. This meant that its production was more important and more enthusiastic than ever before in history.

Have a unique rubber challenge? Need professional insight?

Rubber After World War II

Many of the foundational synthetic rubbers like isoprene, neoprene, and butyl rubber were developed before WWII, but the urgency of the war effort catapulted these materials into mass production on a global scale. These wartime innovations didn’t just meet the demands of that era; they laid the groundwork for rubber technologies that are still in use today.

Established rubber manufacturers like AirBoss have built upon these historical foundations, continually innovating in both compound formulation and manufacturing processes. The widespread use of these various rubber compounds owes its genesis, in part, to the accelerated developments that originated during WWII.

In today’s landscape, the legacy of WWII-era rubber innovation still reverberates. AirBoss Defense Group (ADG), a subsidiary of AirBoss of America, exemplifies this enduring impact. Specializing in survivability solutions, ADG leverages decades of rubber expertise to deliver critical capabilities to defense and healthcare personnel around the world.