RESEARCH & DEVELOPMENT

Superior High-Temperature Resistant Novel EDPM

Long-term Stability

Polymer optimization provides long-term heat aging stability

Improved Processability

Processes easier than other high heat resistant compounds

Cost-Effective Alternative

Durable alternative to comparable high-cost silicone rubbers

Advanced Performance for a Fraction of the Cost

Automakers need a high-performance rubber that can withstand serious temperatures for extended periods of time. HeatBoss® is a cost-effective alternative that outperforms other EDPMs and stands toe-to-toe with silicone rubber where it counts:

- Superior heat resistant properties

- Long-term heat aging stability

- Retains smooth, elastic qualities under high heat

- Better dynamic properties

- Lower density

50-60% Less Expensive

HeatBoss EDPM is 50-60% less expensive than silicone

E and F1 Certified

HeatBoss® EDPM stands more than six weeks hrs at 350 F which makes qualified to pass all type E and F1 standard requirements

17% Less Dense

HeatBoss® EDPM is approximately 17% less dense than silicone alternatives

Processing Made Simpler

Our revolutionary HeatBoss® EDPM outperforms traditional EDPMs and silicones in more than just heat resistance.

Proper polymer selection and formulation optimization means HeatBoss® is easier to process than more expensive alternatives, saving you time and resources.

Superior Heat Aging at a Fraction of the Cost

HeatBoss® EDPM withstands extreme high temperatures for extended periods of time, making it well-suited for specialized automotive applications.

Our novel EDPM displays superior heat aging properties after more than 70 hours of testing at 392 degrees Fahrenheit.

What’s more, HeatBoss® is, on average, 50-60% less expensive than silicone alternatives.

Higher Initial Properties than Silicone

HeatBoss® EDPM exhibits higher initial tensile and elongation properties than traditional silicones used in automotive applications.

HeatBoss® also provides excellent resistance to ozone and oxygen at elevated temperatures.

Better dynamic properties make HeatBoss® EDPM an ideal, high-performing alternative to traditional silicone.

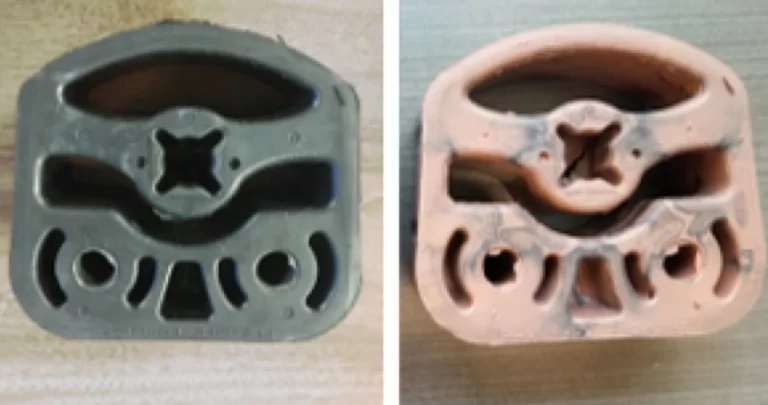

Case Study 01

HeatBoss EPDM was able to be molded in the same way as silicone. The results showed that both HeatBoss EPDM (right sample) and silicone-base (left sample) pass the test successfully. The results once again confirm HeatBoss EPDM can be easily processed and its performance is comparable to that of silicone.

Case Study 02

The back and Front sides of the muffler hanger molded via HeatBoss EPDM. The results showed that HeatBoss EPDM meets the muffler hanger requirements successfully relating to its proper dynamic properties, high tear resistance and heat aging.